How do T-slotted Profile Automatic Connectors contribute to the aesthetics and cleanliness of automation systems?

T-slotted Profile Automatic Connectors contribute to the aesthetics and cleanliness of automation systems in several ways:

Sleek and Modular Design: T-slotted Profile Automatic Connectors are often designed with a sleek and modern appearance, contributing to the overall aesthetic appeal of the automation system. Their modular design allows for clean lines and a streamlined look.

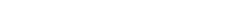

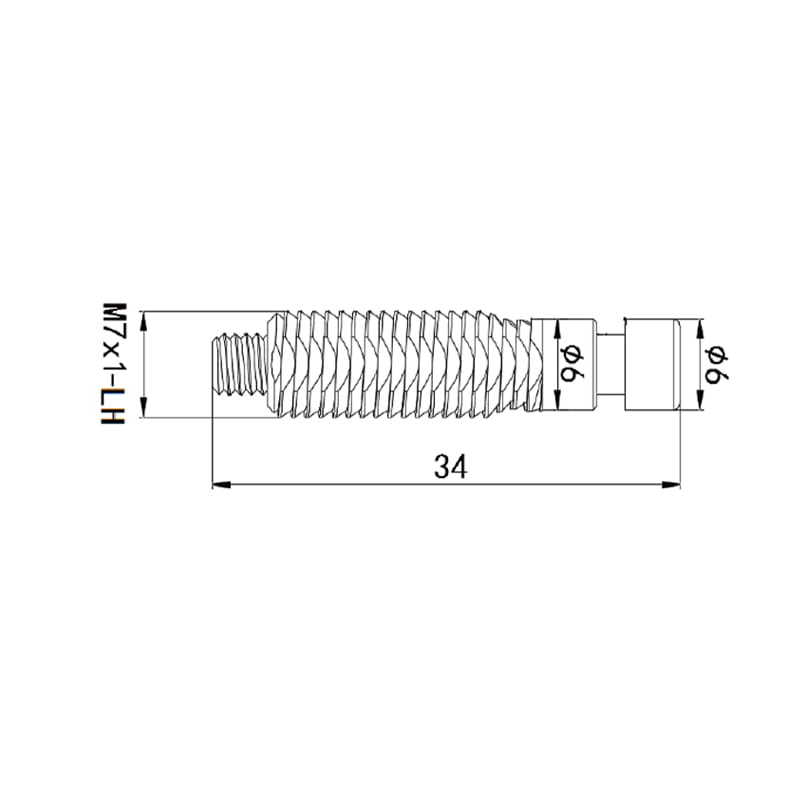

Hidden Fasteners: These connectors are engineered to hide fasteners within the T-slot profiles, providing a cleaner and more polished appearance. This design minimizes the visibility of screws or bolts on the surface, enhancing the aesthetics.

Cable Management Integration: T-slotted profiles often have built-in channels and features for effective cable management. Cables and wiring can be neatly routed within the profiles, reducing clutter and improving the overall cleanliness of the system.

Flush Surfaces: T-slotted Profile Automatic Connectors contribute to flush surfaces when connecting profiles. This design choice minimizes protrusions or uneven surfaces, enhancing the sleek look of the automation framework.

Enclosed Profiles: Some T-slotted profiles feature enclosed or semi-enclosed designs, preventing dust and debris from accumulating within the profile channels. This enclosure helps maintain a cleaner and more hygienic environment in sensitive applications.

Smooth Joints: Automatic connectors facilitate smooth joints between connected profiles, avoiding gaps or misalignments that could collect dirt or impede the clean lines of the system.

Corrosion-Resistant Materials: The materials used in

T-slotted Profile Automatic Connectors are often corrosion-resistant, ensuring long-term durability and a clean appearance over time, especially in industrial environments.

Easy-to-Clean Surfaces: The materials and finishes of T-slotted profiles are chosen for their ease of cleaning. Smooth surfaces and non-porous materials make it simpler to maintain a clean and hygienic automation system.

Color Options: T-slotted profiles and connectors may come in various colors or finishes, allowing designers to match the system with the overall color scheme of the facility or choose options that promote a clean and professional appearance.

Integrated Accessories: T-slotted profiles often support the integration of accessories such as covers, panels, or doors. These accessories contribute to the cleanliness by enclosing and protecting internal components, preventing dust accumulation.

Minimal Maintenance Requirements: The design of T-slotted Profile Automatic Connectors, with hidden fasteners and enclosed profiles, contributes to systems with lower maintenance requirements, promoting cleanliness by reducing the need for frequent adjustments or repairs.

Hygienic Materials: In applications where cleanliness is critical, T-slotted Profile Automatic Connectors may be available in materials that meet hygienic standards, ensuring compatibility with cleanroom or food industry requirements.

By focusing on design elements that reduce visual clutter, facilitate cable management, and promote easy cleaning, T-slotted Profile Automatic Connectors contribute to the overall aesthetics and cleanliness of automation systems, making them suitable for a wide range of applications.