1.Introduction: Understanding the Profile Square Nut with Spring Leaf

In the realm of fastening technologies, the

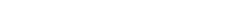

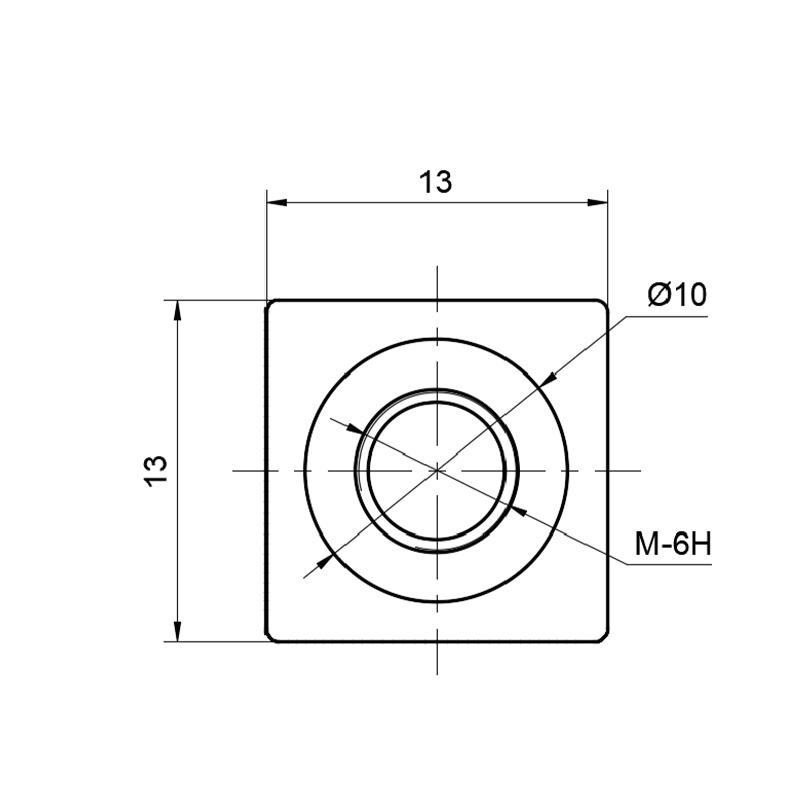

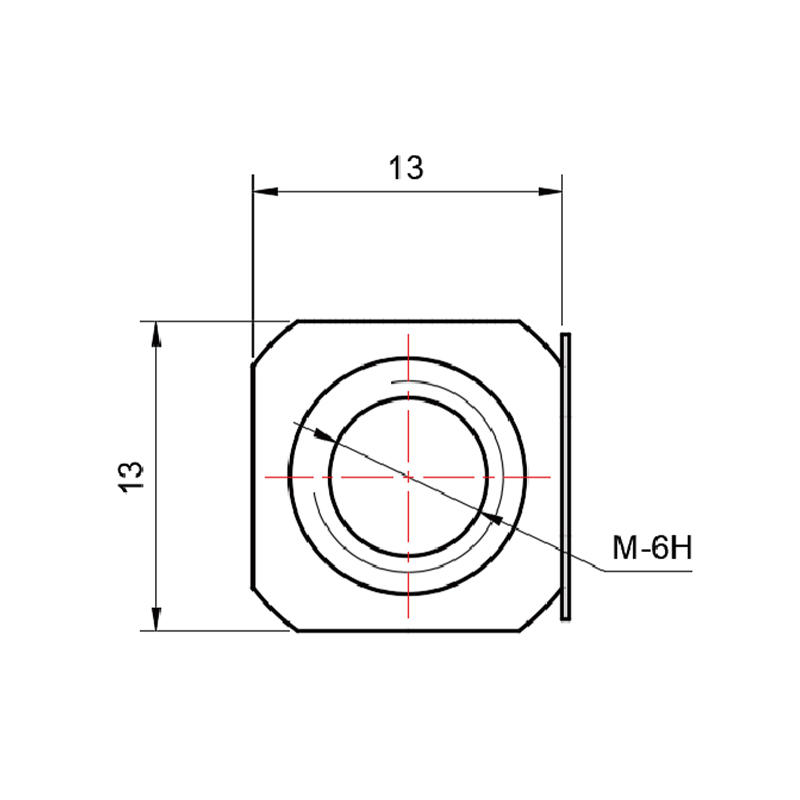

profile square nut with spring leaf emerges as a versatile and efficient solution, revolutionizing the way components are secured in various assemblies. This innovative component integrates the fundamental functionality of a square nut with the added benefits of a spring leaf mechanism, thereby enhancing the overall stability, security, and ease of assembly processes.

Traditionally, square nuts have been widely employed in a multitude of applications, offering reliable fastening capabilities across diverse industries. However, the evolution of engineering standards and the demand for enhanced performance have spurred the development of novel fastening solutions like the profile square nut with spring leaf.

The incorporation of a spring leaf mechanism represents a paradigm shift in fastening technology, as it addresses common challenges associated with traditional square nuts, such as loosening due to vibration or inadequate grip. By integrating this innovative feature, engineers and manufacturers can achieve heightened levels of precision, reliability, and efficiency in their assembly operations.

The profile square nut with spring leaf epitomizes the fusion of traditional craftsmanship with modern engineering principles, embodying a synergy of form and function that empowers industries to push the boundaries of innovation and excellence.

2.Engineering Superiority of the Profile Square Nut with Spring Leaf

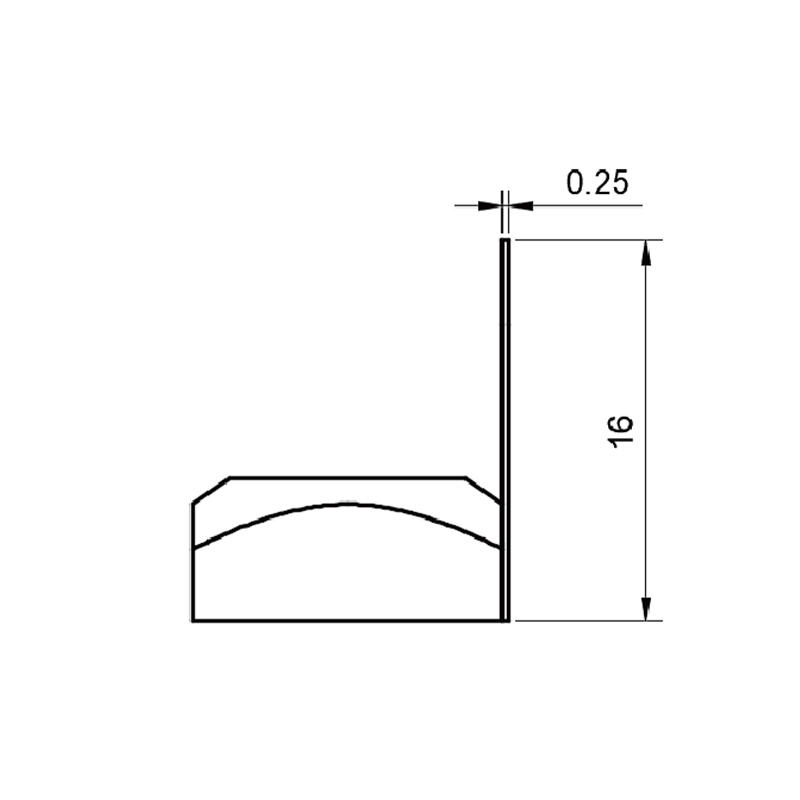

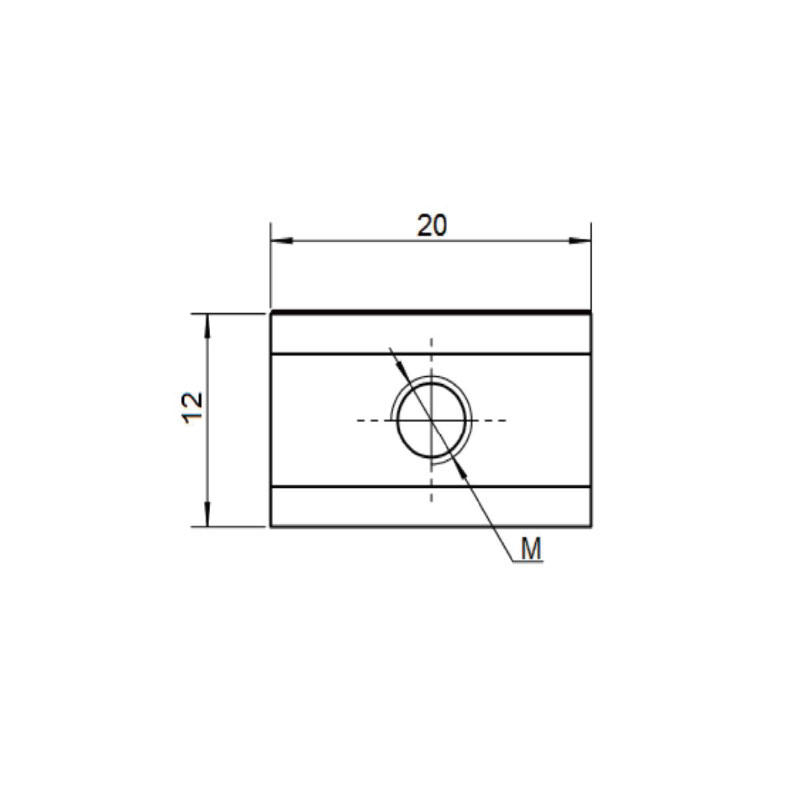

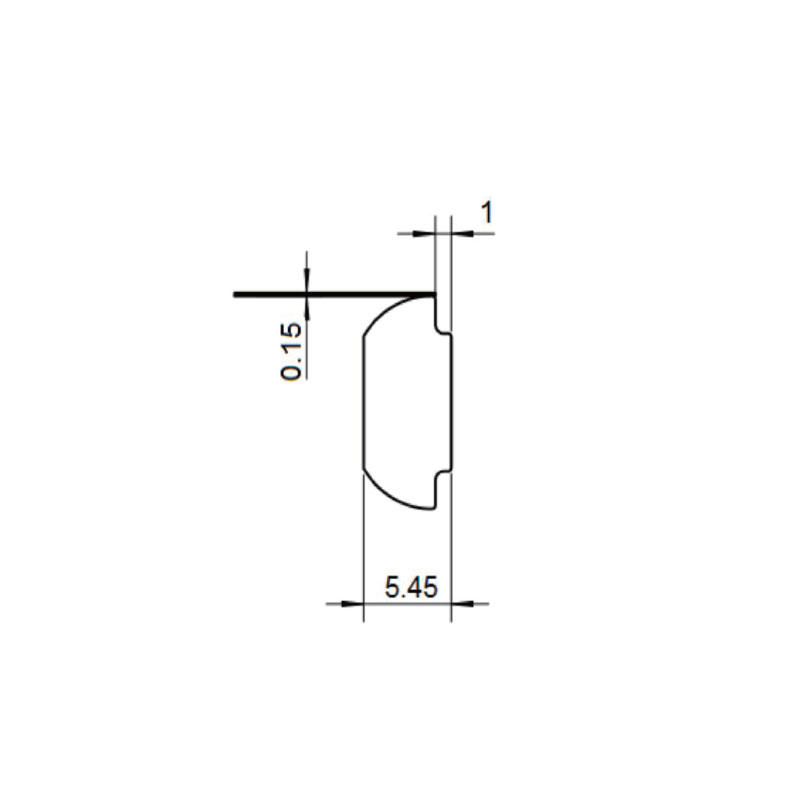

Enhanced Structural Integrity and Load Distribution: The profile square nut with spring leaf introduces a paradigm shift in fastening technology by enhancing structural integrity and load distribution in assemblies. Unlike conventional square nuts, which rely solely on thread engagement for stability, the spring leaf mechanism ensures uniform clamping force distribution across the mating surfaces.

This innovative feature mitigates stress concentrations and minimizes the risk of localized deformation or fatigue failure, thereby extending the service life of components and enhancing overall system reliability. By optimizing load distribution, the profile square nut with spring leaf enables engineers to achieve higher levels of performance and safety in critical applications, ranging from aerospace structures to industrial machinery.

Efficient Preloading and Tension Control: Achieving optimal preload and tension control is essential for ensuring the integrity and performance of mechanical assemblies. The profile square nut with spring leaf streamlines this process by providing a controlled and repeatable method for applying preload to fasteners.

The inherent elasticity of the spring leaf mechanism allows for precise adjustment of clamping force, facilitating uniform tension distribution across multiple fasteners within the assembly. This capability is particularly advantageous in applications where precise torque specifications are required to maintain joint integrity and prevent premature loosening or failure.

Moreover, the ability to adjust preload without disassembly simplifies maintenance procedures and reduces downtime, enhancing operational efficiency and minimizing lifecycle costs. Whether used in automotive engine mounts or structural steel connections, the profile square nut with spring leaf offers unparalleled control over preload and tension, empowering engineers to optimize the performance and longevity of their assemblies.

Resilience to Dynamic Loading and Environmental Factors: Operating environments characterized by high levels of vibration, shock, and thermal fluctuations pose significant challenges to traditional fastening systems. The profile square nut with spring leaf is specifically engineered to withstand these adverse conditions, offering enhanced resilience and durability in demanding applications.

The spring leaf mechanism acts as a damping element, absorbing energy and dissipating vibrations to prevent loosening and maintain joint integrity over time. This damping effect is particularly beneficial in automotive suspension systems, where road-induced vibrations and impacts can compromise the stability and comfort of the vehicle.

Furthermore, the profile square nut with spring leaf exhibits superior resistance to corrosion, abrasion, and chemical exposure, making it well-suited for use in harsh industrial environments and outdoor installations. By incorporating advanced materials and coatings, manufacturers can enhance the longevity and performance of the profile square nut with spring leaf, ensuring reliable operation in even the most challenging operating conditions.