At Ningbo Minde Technology, we proudly present our flagship product, the Profile Pivot Joints, meticulously engineered from high-quality Zinc alloy material. These Pivot Joints are the cornerstone of our production range, setting new standards for modular structure assembly.

Precision Engineering:

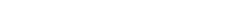

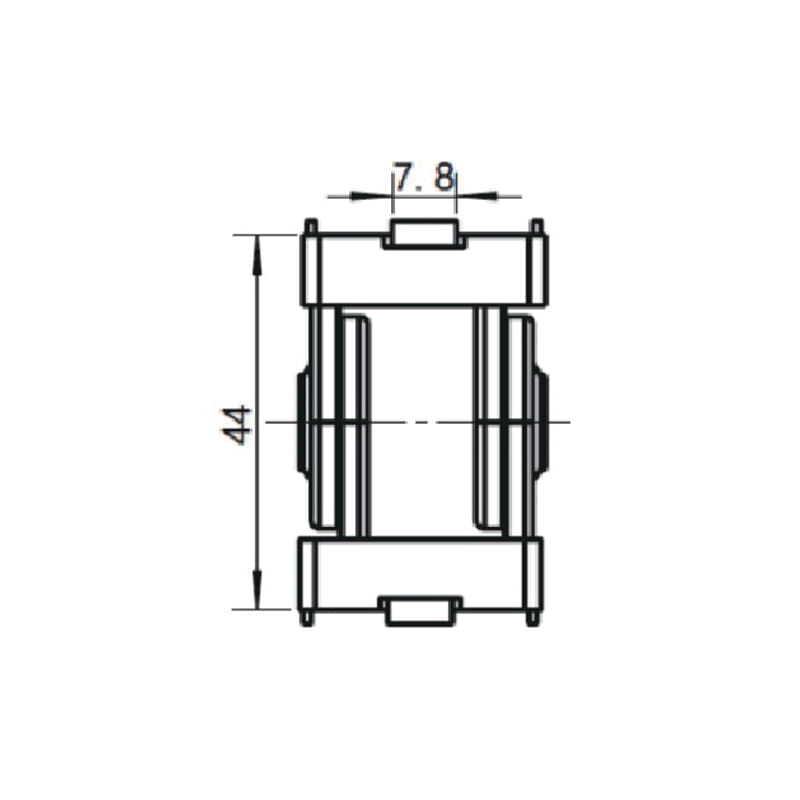

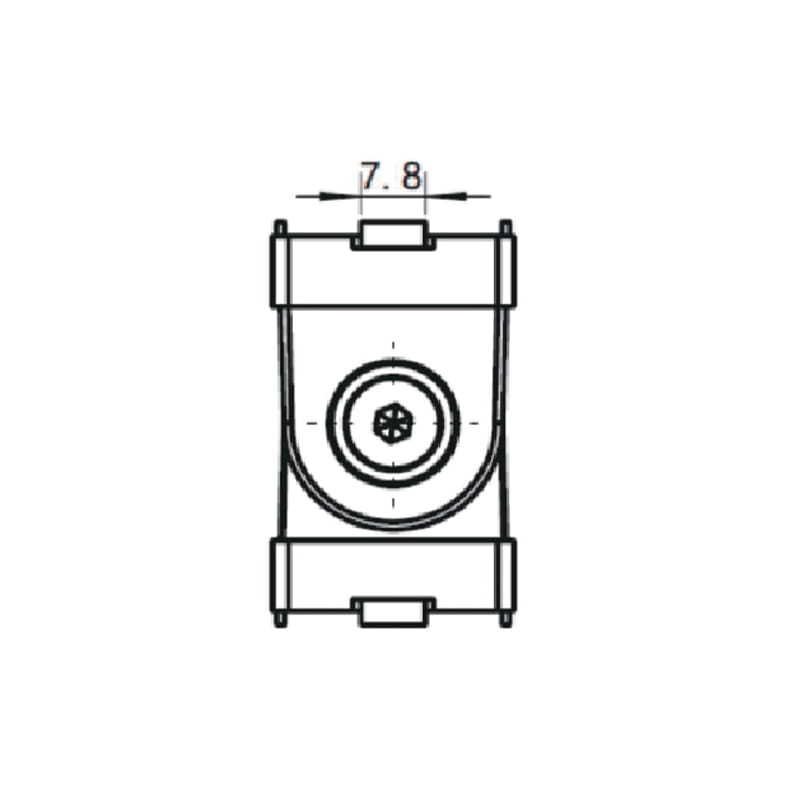

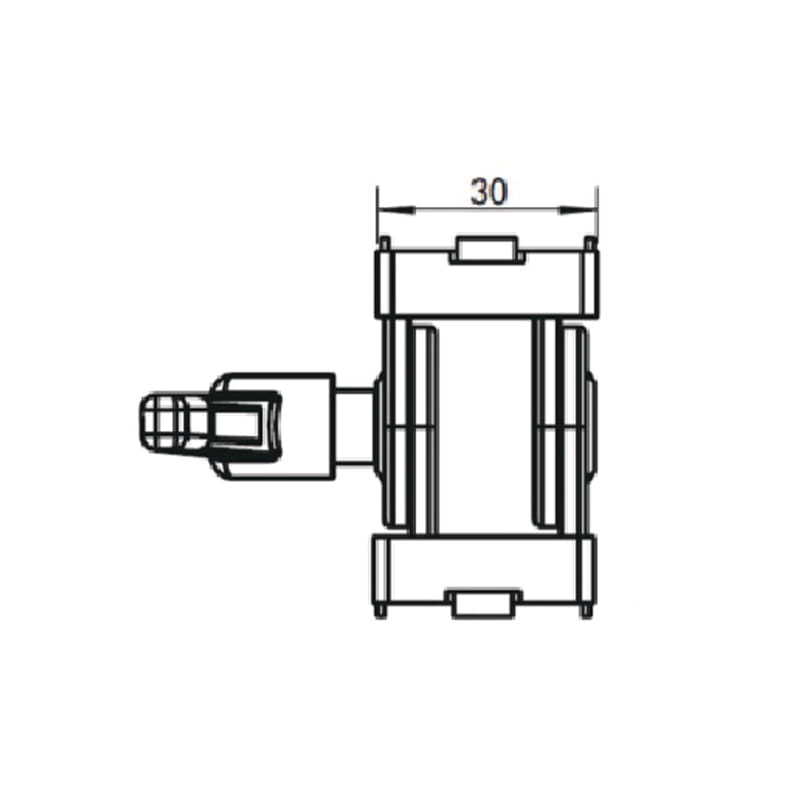

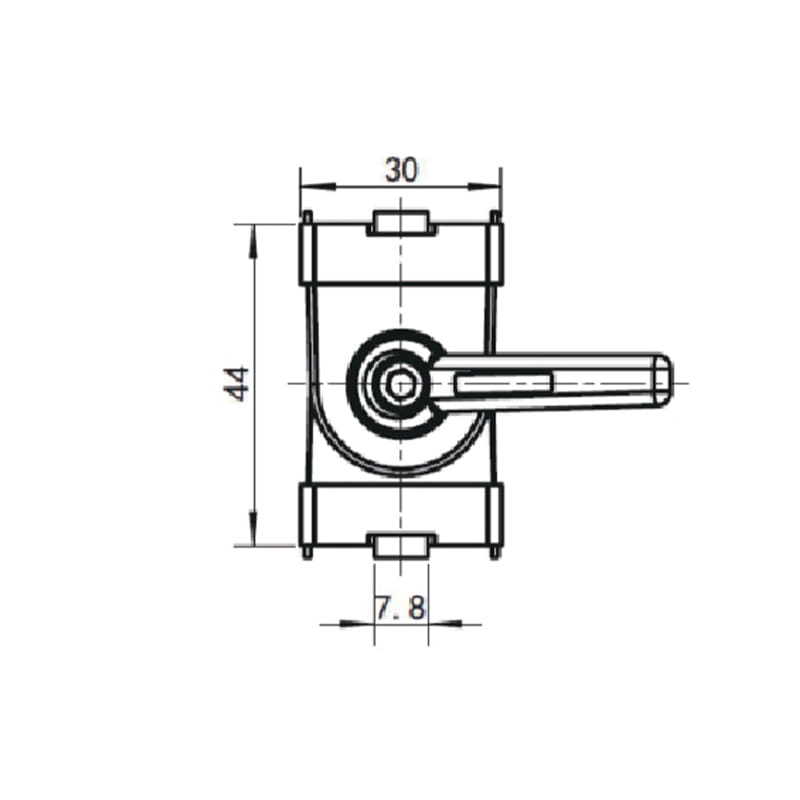

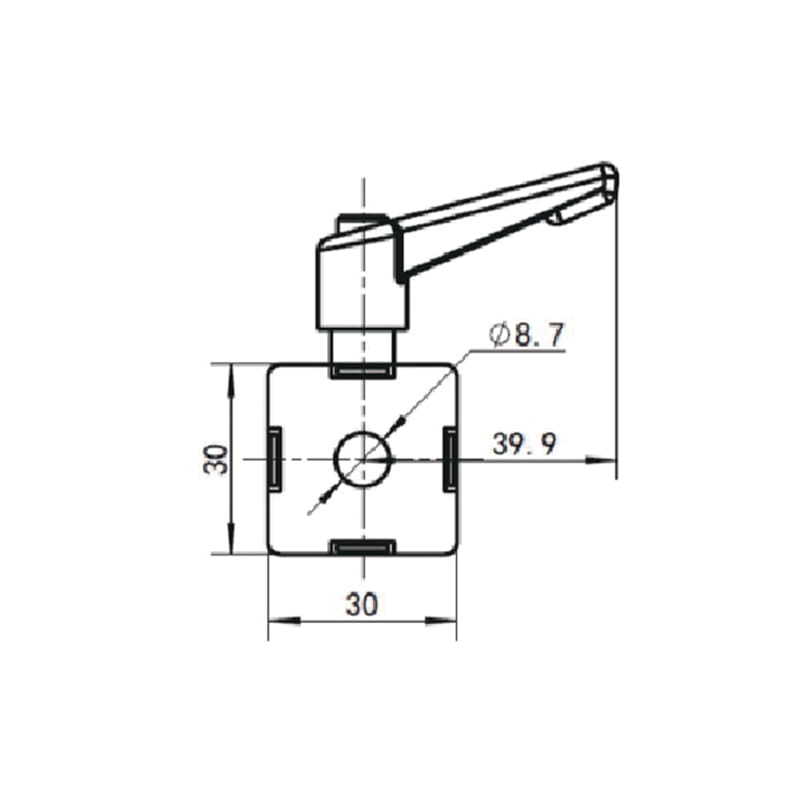

Our Profile Pivot Joints embody precision in every aspect. Crafted with meticulous attention to detail, they ensure seamless articulation and rotation between T-slot aluminum profiles, facilitating the creation of dynamic and adaptable structures.

Smooth Articulation:

Designed for controlled articulation, our Pivot Joints enable smooth and precise movement between profiles. They are ideal for creating joints, pivoting connections, and articulating elements within your structures.

Strength and Reliability:

Strength and reliability are non-negotiable in automation and manufacturing. Our Pivot Joints are built to withstand demanding conditions, ensuring that your structures remain stable and dependable over time.

Zinc Alloy Material:

These Pivot Joints are crafted from high-quality Zinc alloy material, known for its strength and durability. The use of Zinc alloy guarantees long-lasting performance and corrosion resistance.

Customization for Your Needs:

We understand that each project is unique. Our team collaborates closely with you to provide Pivot Joints tailored to your precise specifications. Whether it's variations in dimensions, angles, or unique design requirements, we have the expertise to deliver customized solutions.

In-House Production Excellence:

Minde Technology takes pride in its in-house production capabilities. This ensures that every Profile Pivot Joint undergoes stringent quality control measures, resulting in consistent performance and reliability.

Unlock Infinite Possibilities:

With Profile Pivot Joints from Ningbo Minde Technology, your projects gain access to limitless possibilities. Our connectors provide the foundation for constructing dynamic, adaptable, and professional-grade structures in various industries.

In conclusion, our Profile Pivot Joints represent the blend of precision, durability, and flexibility in modular structure assembly. With our 19 years of experience and unwavering commitment to excellence, we empower your projects with the finest connectors available in the industry. Experience precision engineering at its with Minde Technology.