Are zinc casting gussets suitable for both indoor and outdoor applications, considering factors like corrosion resistance?

Zinc casting gussets can be suitable for both indoor and outdoor applications, and their performance is often influenced by factors such as corrosion resistance. Here are key considerations:

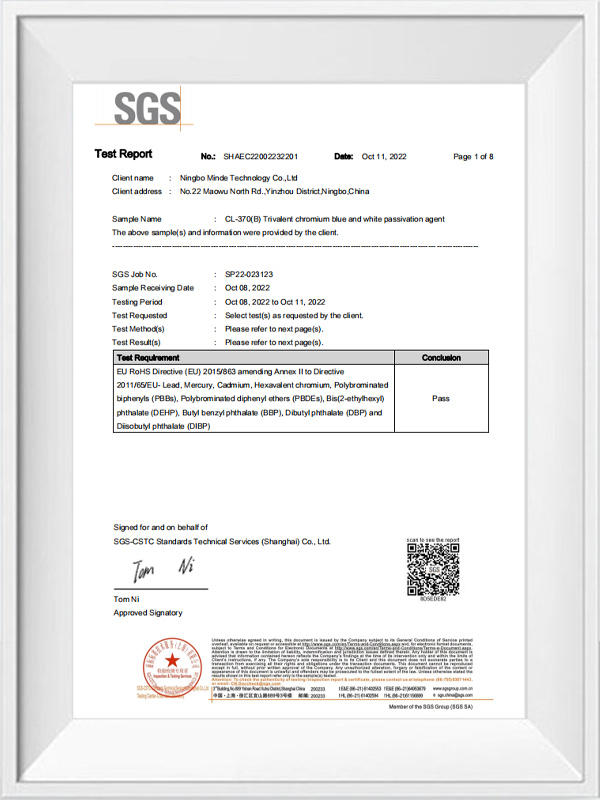

Corrosion Resistance:Zinc offers natural corrosion resistance, forming a protective layer (zinc oxide or hydroxide) when exposed to the atmosphere. This makes zinc casting gussets suitable for outdoor applications where they may be exposed to varying weather conditions.

Indoor Applications:In indoor environments, where exposure to moisture and harsh weather elements is minimal, zinc casting gussets perform well. They are often used in indoor structures, furniture, and equipment.

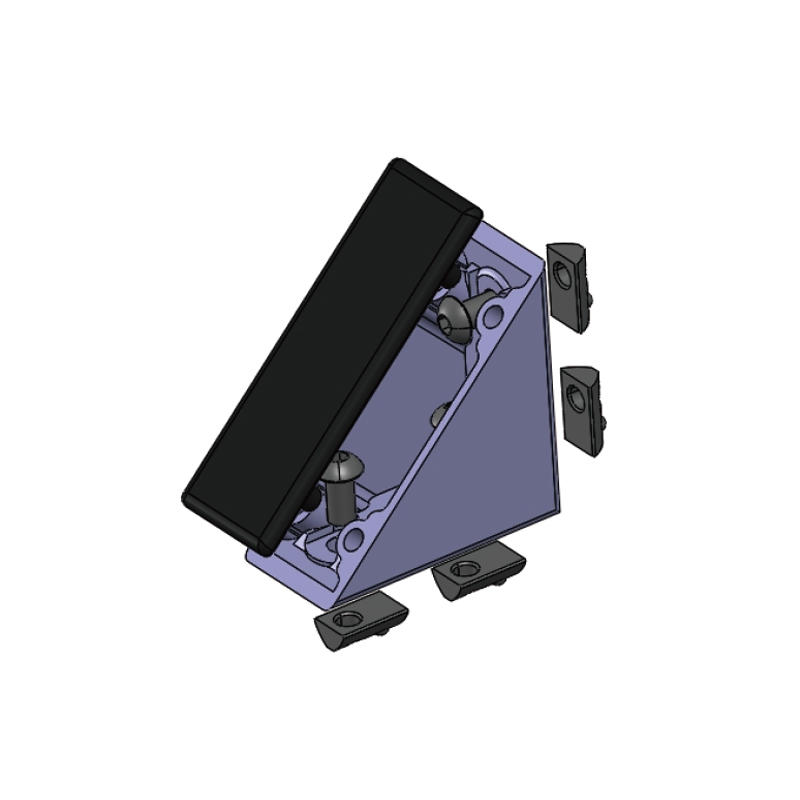

Outdoor Applications:Zinc casting gussets are commonly employed in outdoor applications due to their corrosion resistance. They are used in structures like outdoor furniture, architectural elements, and infrastructure components.

Coatings and Finishes:Additional coatings or finishes, such as powder coating or protective sealants, can be applied to zinc casting gussets to enhance their corrosion resistance. This is especially important in environments with high humidity, salt exposure, or pollutants.

Durability:The inherent durability of zinc, combined with proper surface treatments, contributes to the long-lasting performance of zinc casting gussets. This is beneficial in both indoor and outdoor settings.

Aesthetic Considerations:

Zinc casting gussets can also contribute to the aesthetics of structures, whether indoors or outdoors, due to their versatile design and finish options.

Maintenance:While zinc has good corrosion resistance, occasional maintenance may be required in outdoor applications to ensure optimal performance. This may involve cleaning and reapplying protective coatings if needed.

Environmental Conditions:Extreme environmental conditions, such as high levels of pollution or harsh chemicals, may impact the corrosion resistance of zinc casting gussets. In such cases, proper consideration and additional protective measures may be necessary.

Sustainability:Zinc is a recyclable material, contributing to the sustainability of structures and products that use zinc casting gussets. This eco-friendly aspect is relevant to both indoor and outdoor applications.

Compatibility with Other Materials:Zinc casting gussets can be compatible with various materials, allowing for versatile applications in both indoor and outdoor settings. They can be integrated into hybrid constructions using different materials.

The corrosion resistance of zinc, coupled with appropriate coatings and maintenance practices, makes zinc casting gussets suitable for a wide range of applications, including both indoor and outdoor environments. Careful consideration of environmental conditions and proper surface treatments can further enhance their performance and longevity.