1. What are Profile T Nuts/Hammer Nuts?

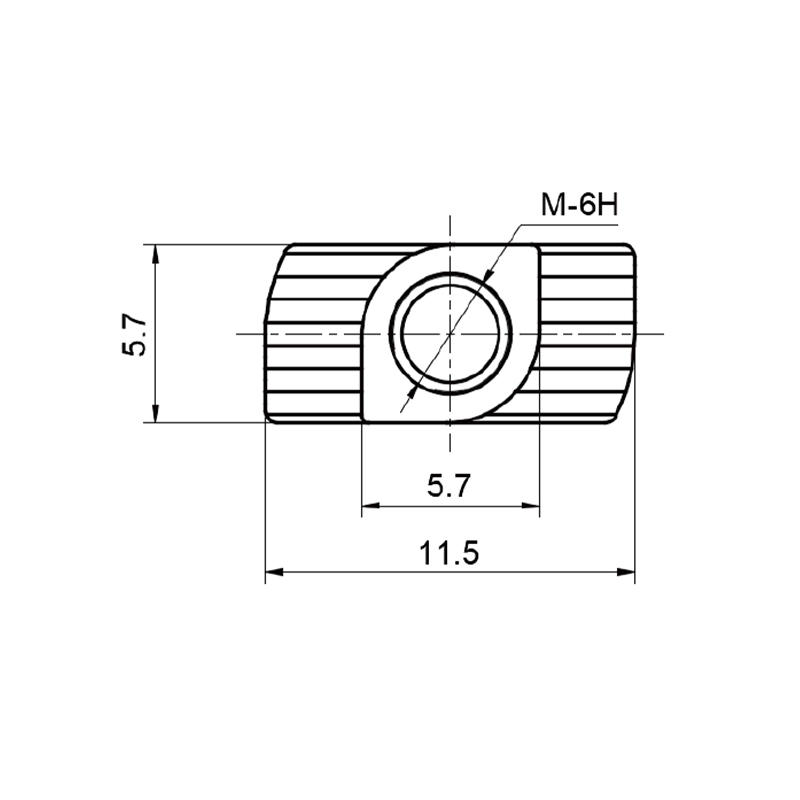

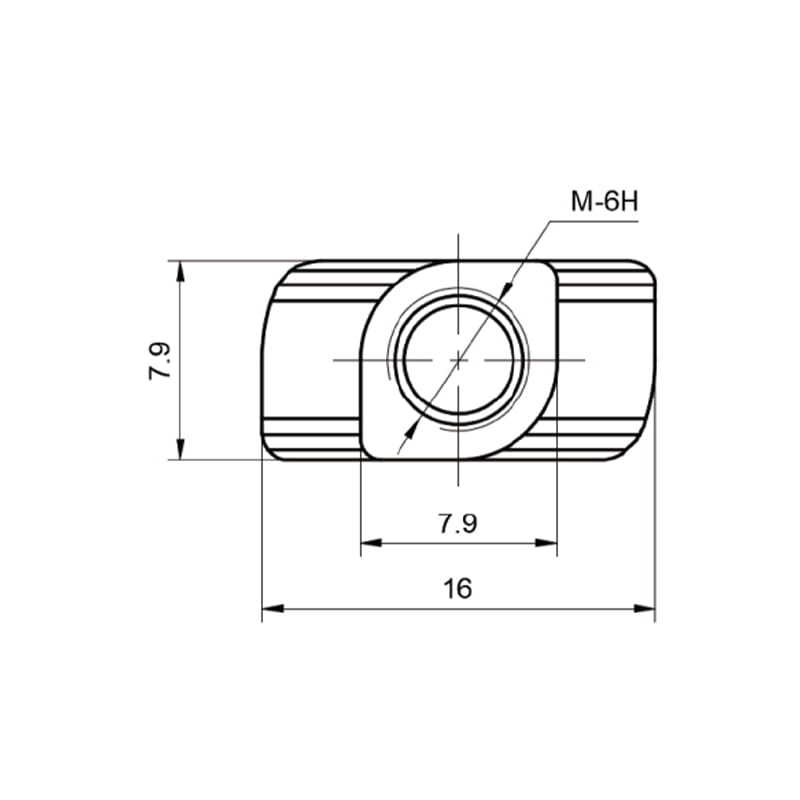

Profile T nuts / hammer nuts are a type of connecting element commonly used in industry, specially designed for use in T-channel systems. They are usually made of metal and have a special shape and structure that allow them to be easily inserted and fixed in the T-channel. The shape and size of these nuts make them a perfect match for the T-channel, ensuring a solid connection and reliable support. In the field of industrial production and machine building, Profile T Nuts / Hammer Nuts are widely used in various assembly and connection tasks.

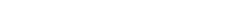

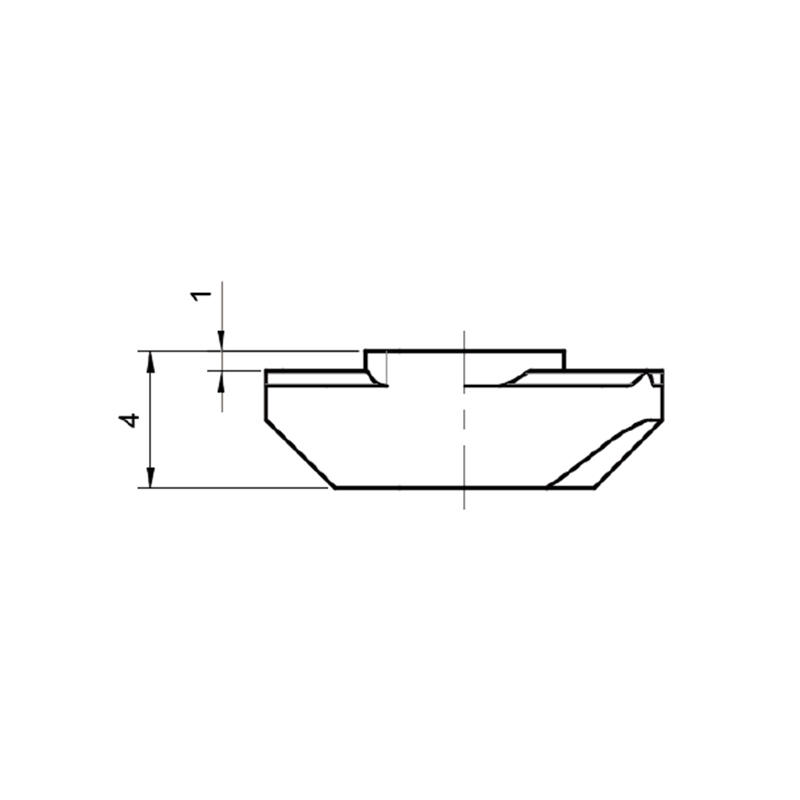

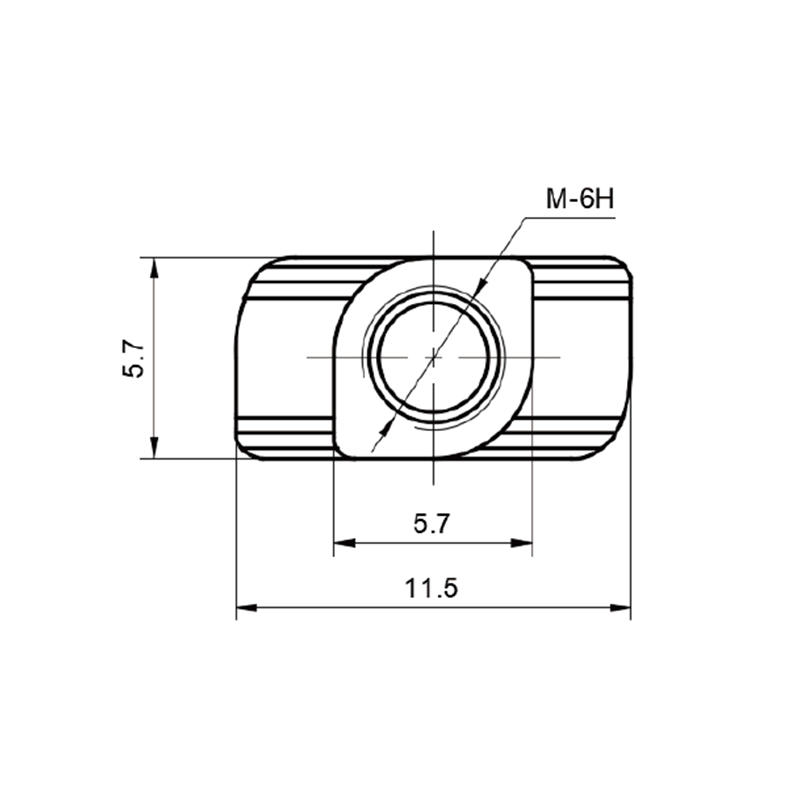

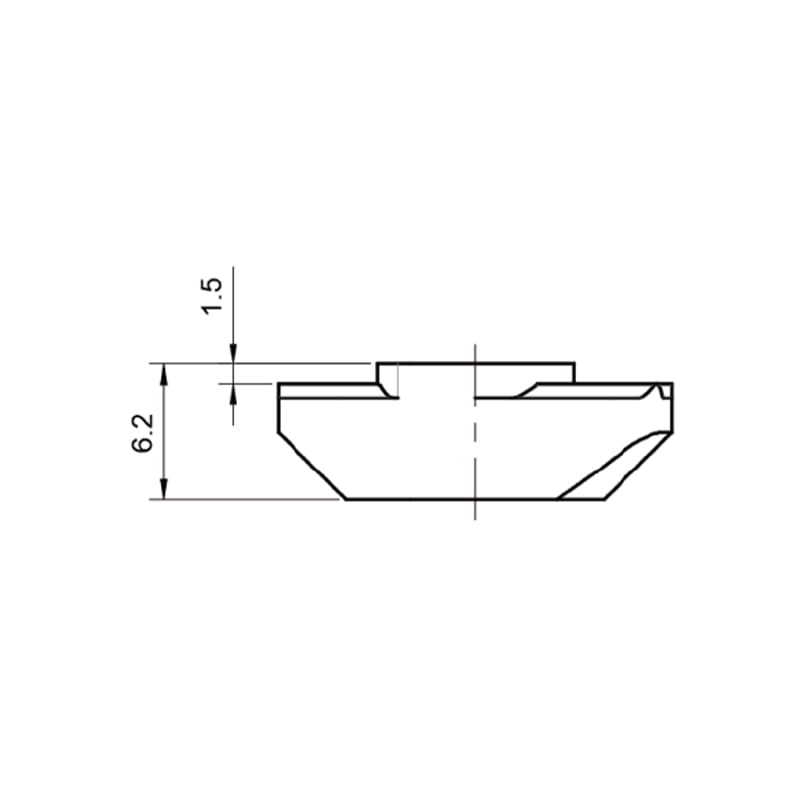

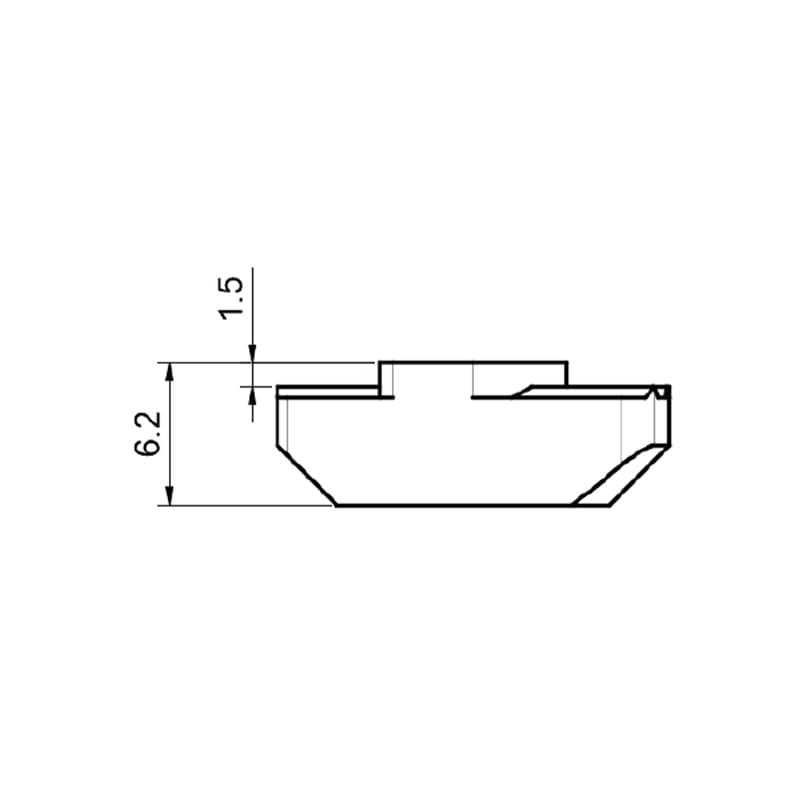

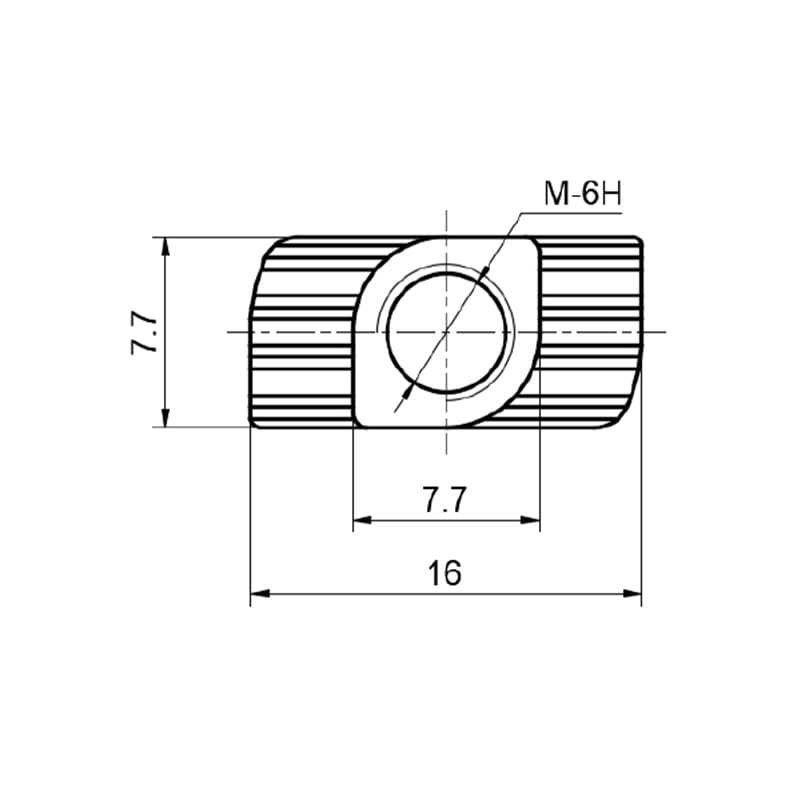

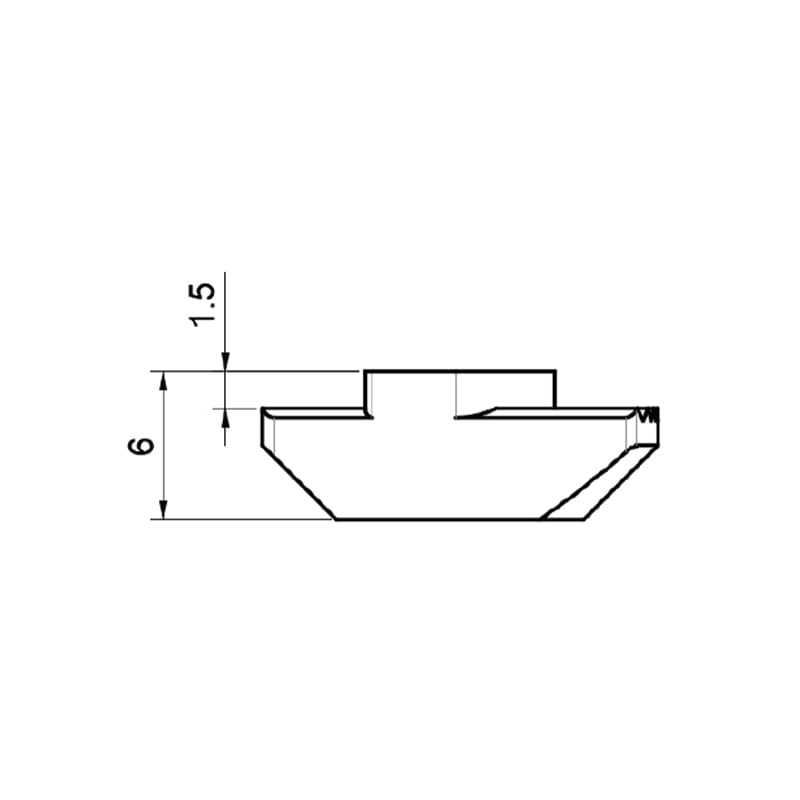

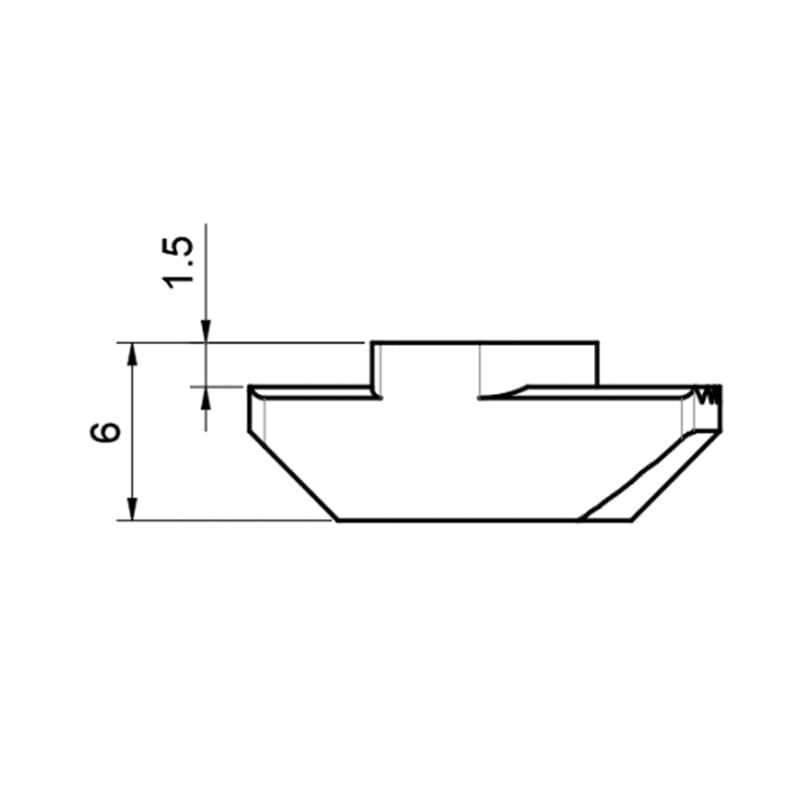

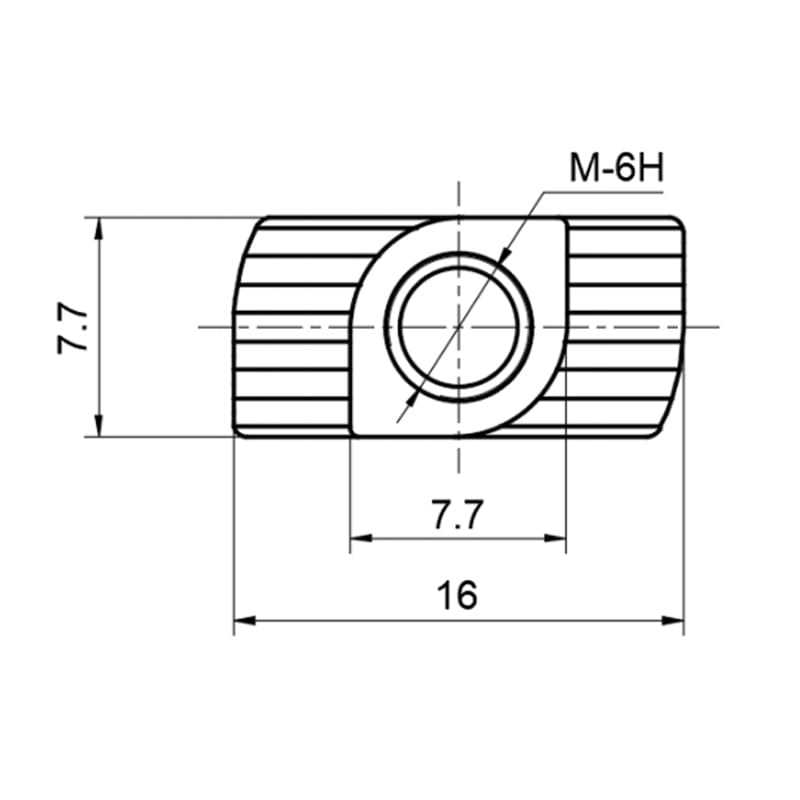

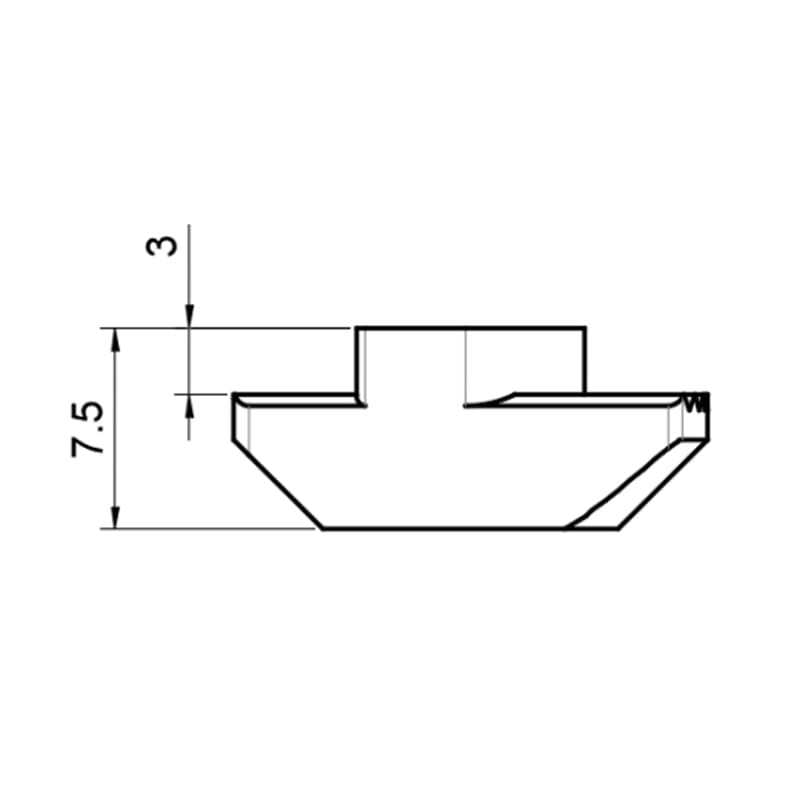

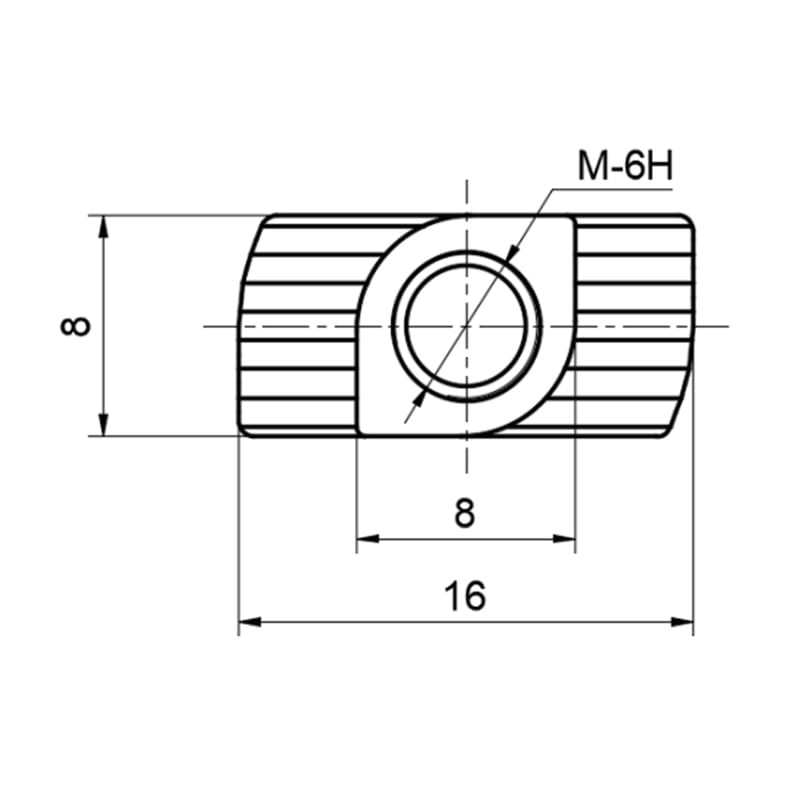

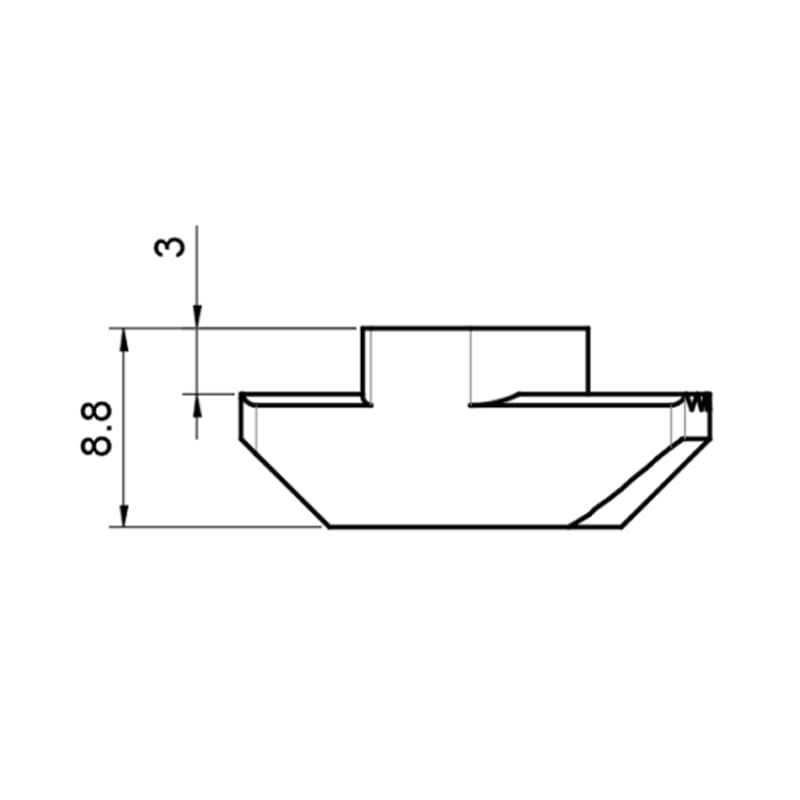

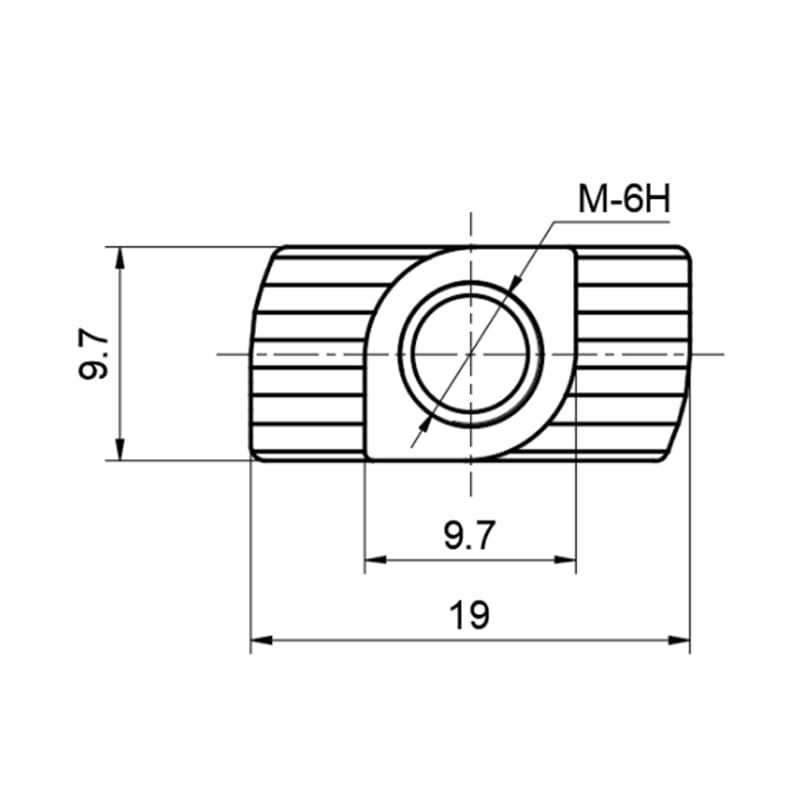

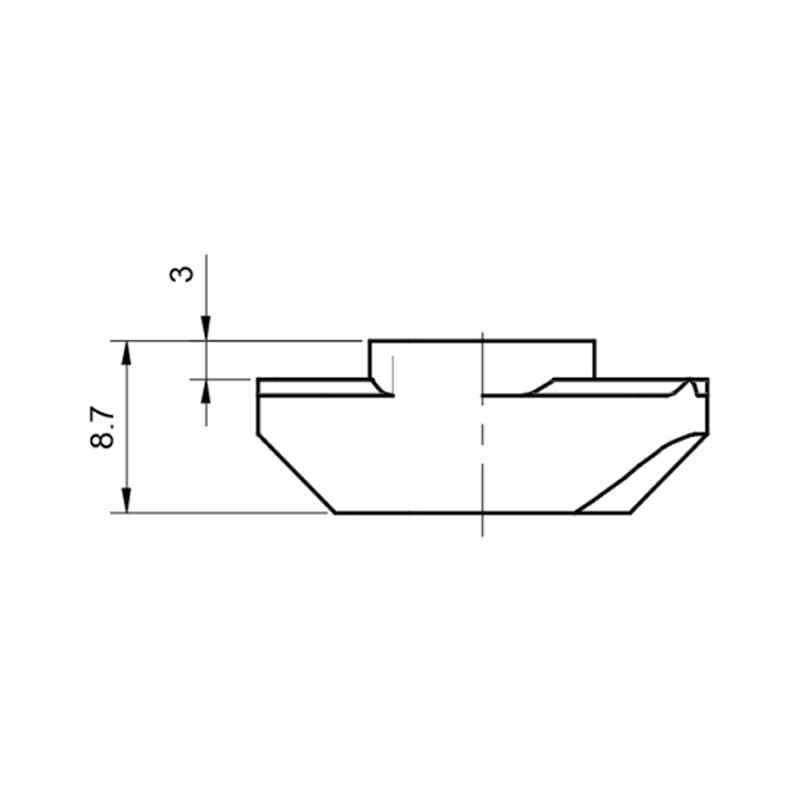

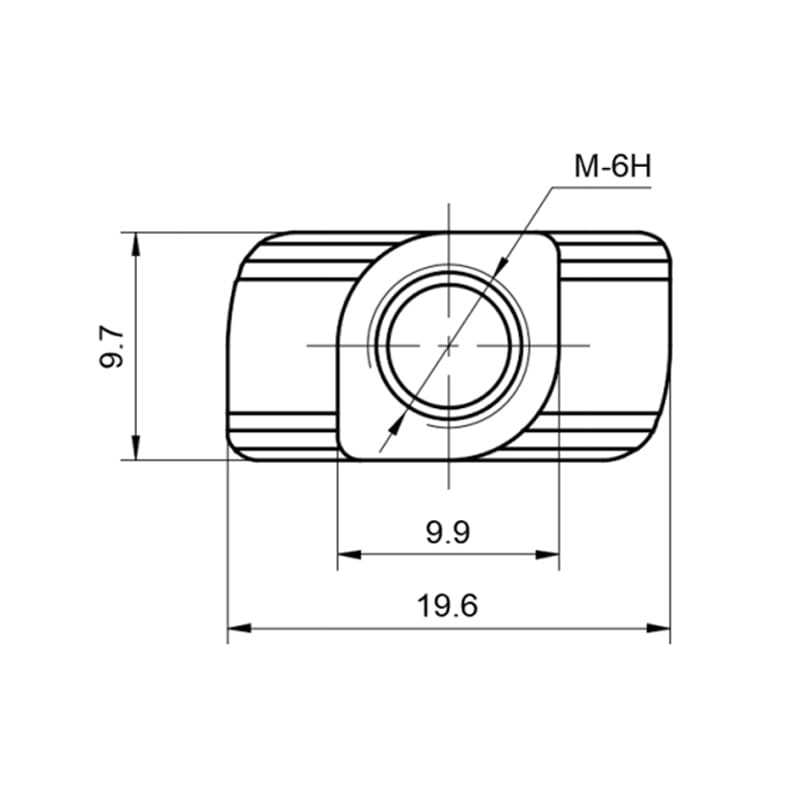

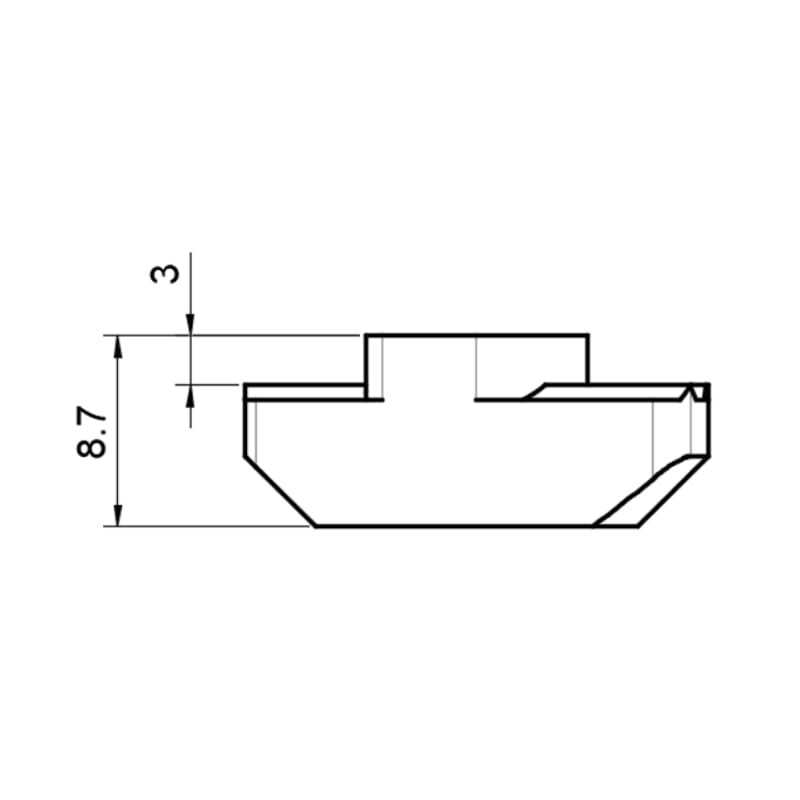

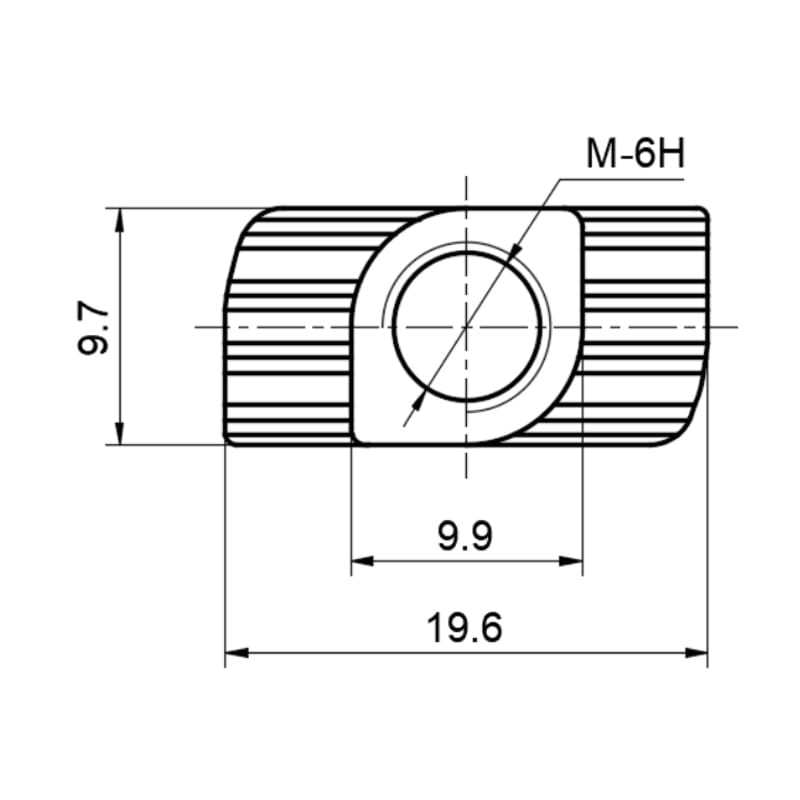

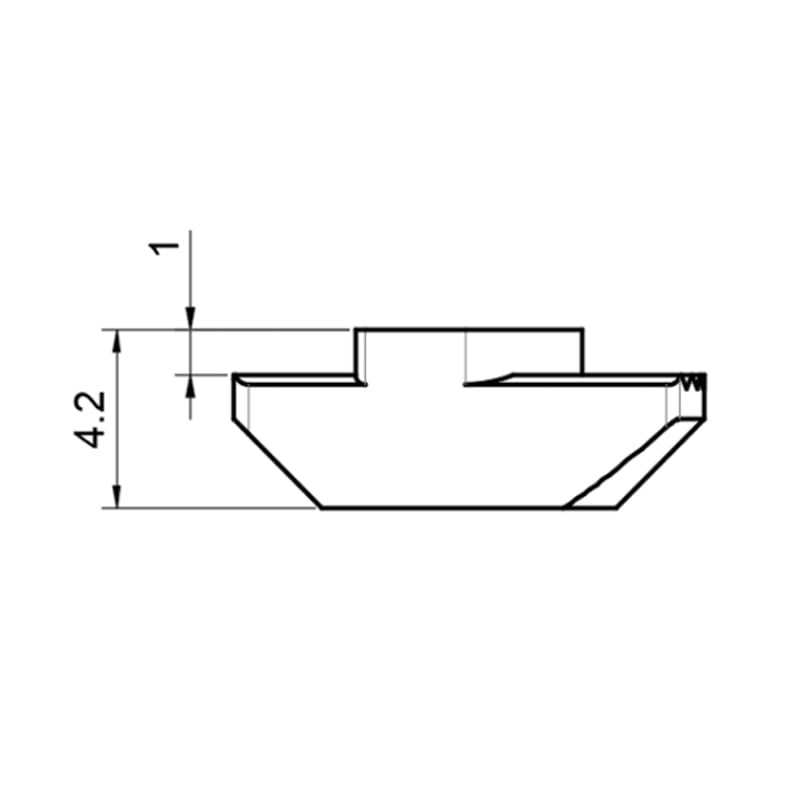

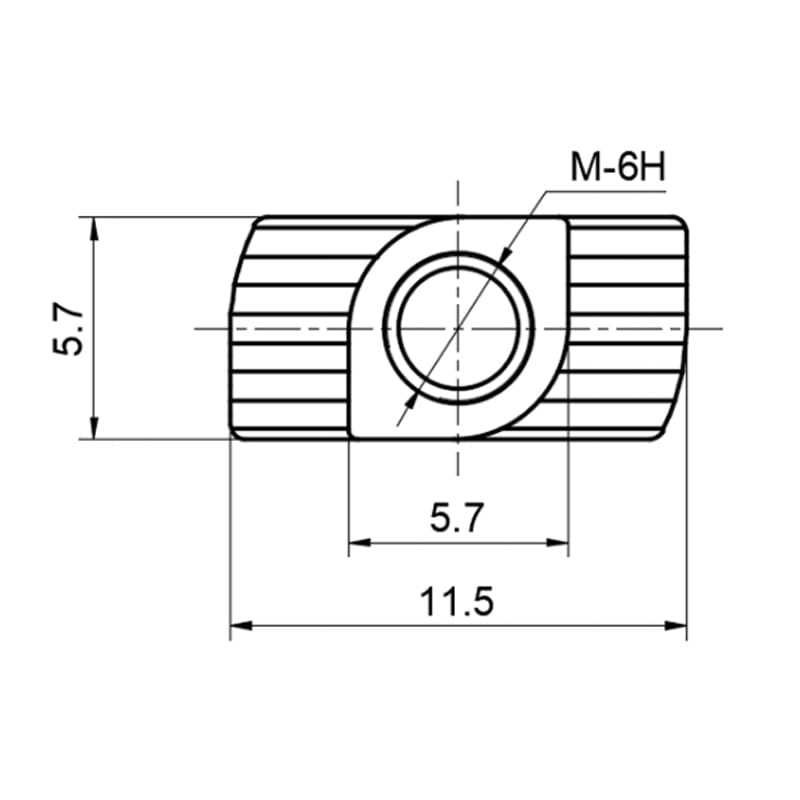

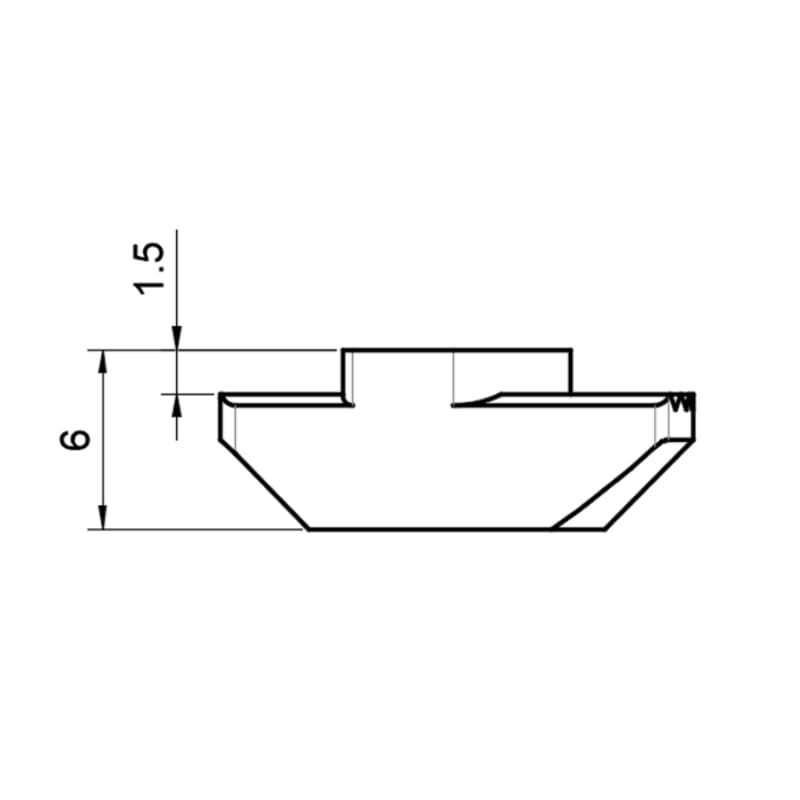

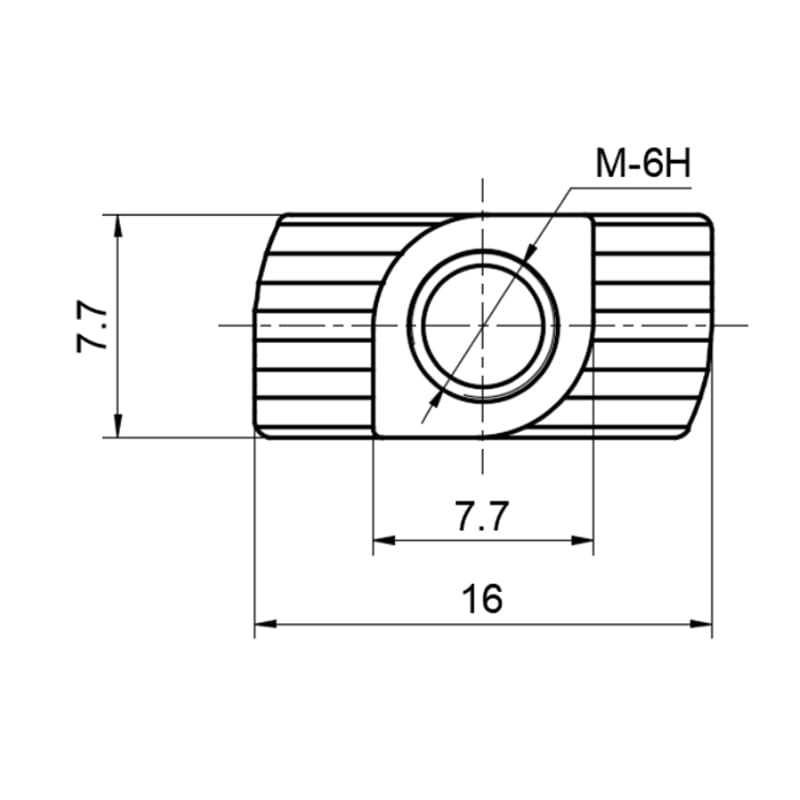

These nuts are usually made of high-quality metal, such as steel or aluminum alloy, to ensure their durability and strength. They are engineered to withstand high levels of torque and pressure, making them an integral part of industrial applications. Profile T Nuts/Hammer Nuts are typically T-shaped or pear-shaped in appearance, with special notches or protrusions for insertion into the T-channel. This design allows it to be easily used with other components and provides a secure connection.

In industrial design, T-channel systems are usually used for the assembly and installation of brackets, racks, fixed frames and other structures. The introduction of Profile T Nuts / Hammer Nuts makes the assembly process of these structures more efficient and convenient. Furthermore, they are designed so that the installation process does not require any permanent changes or damage to the T-channels, maintaining the integrity and maintainability of the system.

2. What is the design principle of Profile T Nuts/Hammer Nuts?

The design principle of Profile T Nuts / Hammer Nuts is based on their special shape and structure, aiming to provide a fast and reliable connection solution. First, these nuts usually have a T-channel compatible design, allowing them to be easily inserted and secured in the T-channel. Its shape matches the T-channel, ensuring a secure connection and a damage-free installation process.

A distinguishing feature of Profile T Nuts/Hammer Nuts is their hammer nut design compared to traditional nuts. This design allows workers to quickly install and fix it in the T-channel by using a hammer or similar tool, greatly improving installation efficiency and convenience. This installation method can be completed quickly, does not require complex tools or equipment, and is suitable for a variety of working environments and conditions.

The material selection and manufacturing process of Profile T Nuts/Hammer Nuts are also an important part of their design rationale. These nuts are typically made from high-strength metals, such as stainless steel or aluminum alloys, to ensure reliability and durability in high-stress and vibration environments. Its precision machining and surface treatment give it excellent corrosion resistance and surface smoothness, improving its performance and reliability in practical applications.

3. What is the role of Profile T Nuts/Hammer Nuts in industrial applications?

Profile T Nuts/Hammer Nuts play a key joining role in industrial applications, providing reliable joining solutions for a variety of assemblies and structures. They are often used to connect and secure various components, such as metal frames, brackets, mechanical parts, etc. Due to their well-designed and efficient installation methods, Profile T Nuts / Hammer Nuts are widely used in production lines, machinery and equipment, assembly lines and other occasions where reliable connections are required.

Assembly and connection are often a time-consuming and critical step in the industrial manufacturing process. The introduction of Profile T Nuts / Hammer Nuts makes this process more efficient and convenient. Its quick installation and secure connection features can significantly reduce assembly time and increase production line efficiency and productivity.

Profile T Nuts/Hammer Nuts are designed to work in a variety of environments and conditions. Whether on an indoor production line or on an outdoor jobsite, they provide reliable connectivity and perform well in harsh working conditions. This flexibility and reliability have made Profile T Nuts/Hammer Nuts one of the preferred joining elements in industrial applications, providing a solid foundation and support for a variety of applications.